- Design and Preparation of Mechanical Layouts for Industrial /Commercial Projects.

- Preparation of Estimate, Load list, Bill of Quantity & Schedule.

- Site Supervising and Material Purchasing , Structures design Preparation

- Fire Protection & Detection System

- Fire Alarm Sprinkler & Hydrant Line

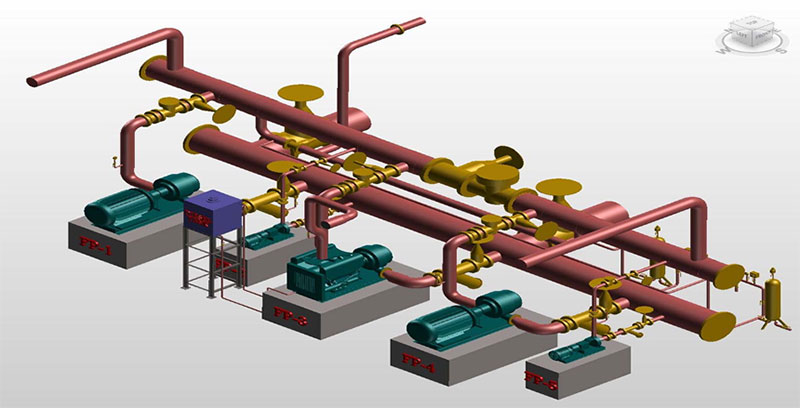

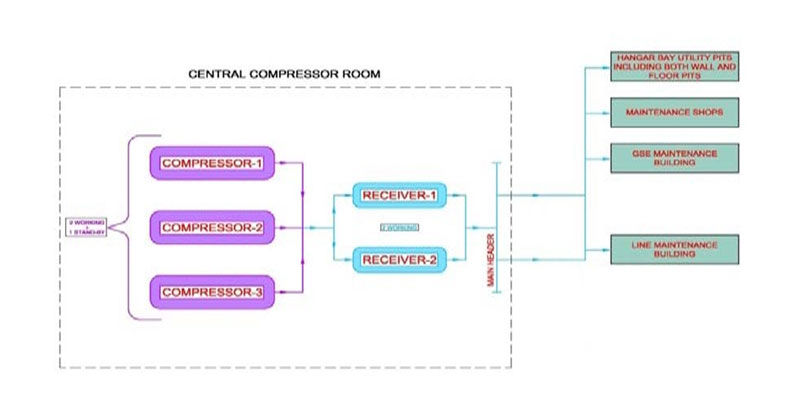

- Air Compressor System with Piping Line

- Cooling Tower System with Piping Line

- Domestic Water System with Piping Line

- ETP & STP System

- Air Conditioner with Ducting System

Mechanical System

Mechanical System

Fire Hydrant System

Fire Protection & Detection system shall be designed & provided, as per

- National Building Code of India - 2005, Part - 4, Fire and Life Safety.

- National Fire protection Association(NFPA)

- Corresponding Bureau of Indian Standards.

- Local Fire Norms

- Wet riser system

- Automatic Sprinkler system

- Analogue Addressable Fire Detection & Alarm system

- Portable First-Aid Fire Extinguishers

- Photo luminescent Safety Signage's

- Fire Rated Sealants

- One number of Electric operated pump for Hydrant system

- One number of Electric operated pump for Sprinkler system

- One number of Common Diesel operated pump for Sprinkler and Hydrant systems

- One number of Jockey pump for Hydrant system

- One number of Jockey pump for Sprinkler system

- Motor Driven terrace Pumpset -3 Nos.

- The yard hydrants shall be oblique type, single headed fixed on the stand post at 45 m intervals around the proposed buildings.

- Each single / double hydrant valve shall be provided with 2 nos. of 15 m hose and 1 no. of branch pipe with Nozzle.

- Minimum pressure of 3.5 kg/cm2 shall be ensured at the remotest hydrant point.

- The external and internal pipes for hydrant system shall be of G.I heavy grade type.The system will have automatic pumping arrangement.

External Yard hydrants along with Wet riser cum Down comer system:

Compressed Air System

- Compressed air is air which is kept under a certain pressure usually greater than that of the atmosphere.

- Compressed air is a form of energy that is safe and versatile. In use, the compressed air will expand back to its original volume, producing energy that can be used to run tools and equipment.

Strengths:- it is clean energy

- in many applications it is safer than electricity

- it allows greater maneuverability

- it offers lighter and more compact tools

- Air compressors produce a viable alternative form of energy, which is safe to use, clean and versatile.

- Manufacturers are able to make high quality machines and tools, which are compact in size, easy to use and very economical.

- Equally, the range of accessories is increasing all the time and pneumatic tools are increasingly becoming a valid alternative to electrical tools in a wider range of applications. Pneumatic tools offer quality, performance and reliability at a very affordable price.

LPG System

- LPG is supplied from cylinder storage bank to the user end through manifold, LPG pipes and valves

- The active and standby cylinders are connected to manifolds placed in individual compartments.

- When the active group runs out of LPG, the operator closes the valve of that group and opens the valve of the standby group.

- The LPG travels through the pipeline and safety equipment before entering the kitchen / cafeteria area. There will be two stage pressure regulation between the gas bank and the end point.

- A pressure relief valve and flame arrestor is provided in the LPG supply line for enhanced safety. Each user end point stops with a pressure regulator and isolation valve.

Aircondition Systems

- Multi V III Air Conditioning Systems

- Ductable split Air Conditioning Systems

- Packaged Air Conditioning Systems

- Cassette and Floor Standing Air Conditioning Systems

- Small Central Plants

- Window & Split Air Conditioning Systems

- Planning & Installation of All Kind of Air conditions Indoor / Ourdoor,

- Servicing and Maintenance of All Kind of Air conditions Indoor / Ourdoor

Nature of Work for Air conditions:

- MS pipe line all sizes fabrication erection and welding work./ all type of pipe line Insulation.Ducting GI ducting / spiral ducting / all type of duct Erecting and insulation..

- Air handling unit all types ceiling mounted and floor mounted erection break down attending coil servicing de-scaling Preventive maintenance, general maintenance.

- Fan coil unit all types ceiling mounted erection break down attending coil servicing preventive maintenance, and general maintenance.All types of cooling tower erection fabrication break down attending basin service FRB work preventive maintenance, and general maintenance.

- All type of HVAC central plant air-conditioning water-cooled and air cooled plant erection Labor maintenance servicing preventive maintenance, and general maintenance break down attending chiller and condenser coil de-scaling .

- All types of chiller & condenser pump’s erection over haling servicing break down attending preventive maintenance and and general maintenance.

- All types of package unit ceiling mounted and floor mounted AMC erection break down attending coil servicing Preventive maintenance and general maintenance.

- All types of split unit and caste unit model AMC erection break down attending coil servicing Preventive maintenance and general maintenance.